LNF PCV Anti-coking drain back system

#226

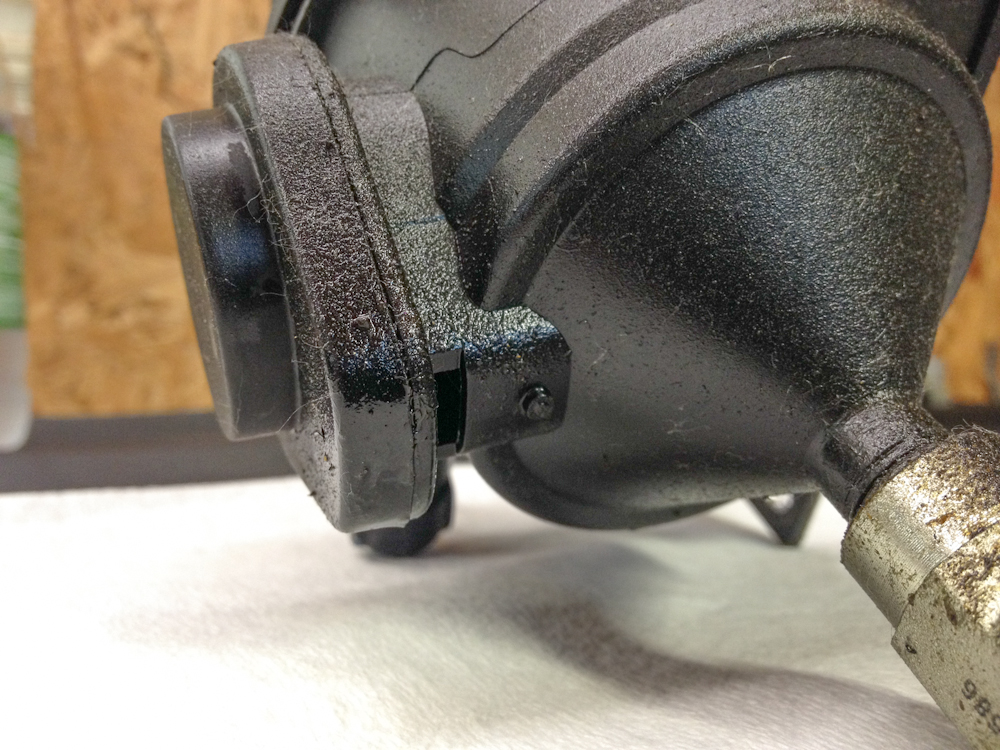

It was at the beginning; then we found that we had to add a check valve in the oil return line as most of the cars have too much blow by and not enough vacuum, especially on the road race track.

Added one check valve with two extra fittings.

#228

I'm a firm believer in the products that Powell brings to our platform with the research, development, and engineering that goes into his products, you'd have to be ignorant to not run them...or poor, but hey I'm also a firm believer in you gotta pay to play. Typically the more you pay, the longer you can play haha.

Speaking of which, 12k later, Japeatr and myself are finally putting together my build in 3 weeks if all goes as planned. Powell's pcv kit, cabs, and bushing replacement are among that last items my build needs that I will be purchasing in April.

Speaking of which, 12k later, Japeatr and myself are finally putting together my build in 3 weeks if all goes as planned. Powell's pcv kit, cabs, and bushing replacement are among that last items my build needs that I will be purchasing in April.

#232

if that upgrade came from us at Powell the fitting has been changed at the bottom. Not sure why. If its not mine then I would either wonder about the plumbing /check valves for drain back or the health of the motor or track use ... you have an HHR? was that installed by Rudy? wondering

#233

also I had another car today in for decoke and install of a PCV UPGRADE and it had a stuck open IM PCV valve. When that happens its awful the coking that occurs. Also if the Upgrade is plumbed wrong it can cause issues. I know of one HHR ( dont know whose it was) where the PCV was installed incorrectly and I never heard back if that was resolved.

Finally I am working on a car that is tracked, it has an upgrade, but the valves were coked previously and its not working well. I did an engine health check and it is a1, pretty much, but I see a fair amount of blow by into the crank case past the rings. Its still healthy, has 150 lbs compression across the board, but a lot of blow by which for the track is an issue. Not sure if the PCV valve is stuck open I will find out tomorrow when I take it apart.

I am working on v.3 for the upgrade with Alan McLure,( big shout out to him for his hard work) I expect track and high hp engines will need assistance to deal with excessive blow by... such assistance will generate more power, so not all a bad thing.

Finally I am working on a car that is tracked, it has an upgrade, but the valves were coked previously and its not working well. I did an engine health check and it is a1, pretty much, but I see a fair amount of blow by into the crank case past the rings. Its still healthy, has 150 lbs compression across the board, but a lot of blow by which for the track is an issue. Not sure if the PCV valve is stuck open I will find out tomorrow when I take it apart.

I am working on v.3 for the upgrade with Alan McLure,( big shout out to him for his hard work) I expect track and high hp engines will need assistance to deal with excessive blow by... such assistance will generate more power, so not all a bad thing.

#234

if that upgrade came from us at Powell the fitting has been changed at the bottom. Not sure why. If its not mine then I would either wonder about the plumbing /check valves for drain back or the health of the motor or track use ... you have an HHR? was that installed by Rudy? wondering

I bought the check valve but it came with smaller AN fittings than everything else and I never installed it.

I'll get some new fittings and see what it does. The routing is how you recommended (the reverse of what the arrow shows on the separator). I have Wiseco pistons with bigger ring end gap than OEM, so that's probably causing more blow by than normal.

#235

you gotta use the check valve thats the problem right there. Folks who claim AN 4 is not big enough for the drain back dont understand how the PCV works. Even AN 6 is overkill for the vent lines, but is convenient. The orifices in the rocker cover are about 3-4 mm... so the issue right now is reversion up the drain back. if you run AN6 on the drain back, how did you modify the diptick tube? The orifice there is designed to be be small enough to restrict flow, to not interfere with vacuum levels. Vacuum without assistance is a fragile thing on an LNF and GM dont or didnt realise that as the car is beaten on the blow by increases. And wisecos have more blow by, I have heard that, so do Diamonds. I may change my motor to improve the oil control lol. But that said, the way we did the drain back even with AN 4 was not enough to stop reversion hence the check valve. And AN6 makes it worse,

If you told me what you needed I would have sent you new lines. so let me know off line if youwant how I can help. I do have some AN 6 tubes; but the check valve would have to be modified, I can do that, to run AN6, but its not clear to me why its needed.... cheers john@powellraceparts.com

If you told me what you needed I would have sent you new lines. so let me know off line if youwant how I can help. I do have some AN 6 tubes; but the check valve would have to be modified, I can do that, to run AN6, but its not clear to me why its needed.... cheers john@powellraceparts.com

#236

you gotta use the check valve thats the problem right there. Folks who claim AN 4 is not big enough for the drain back dont understand how the PCV works. Even AN 6 is overkill for the vent lines, but is convenient. The orifices in the rocker cover are about 3-4 mm... so the issue right now is reversion up the drain back. if you run AN6 on the drain back, how did you modify the diptick tube? The orifice there is designed to be be small enough to restrict flow, to not interfere with vacuum levels. Vacuum without assistance is a fragile thing on an LNF and GM dont or didnt realise that as the car is beaten on the blow by increases. And wisecos have more blow by, I have heard that, so do Diamonds. I may change my motor to improve the oil control lol. But that said, the way we did the drain back even with AN 4 was not enough to stop reversion hence the check valve. And AN6 makes it worse,

If you told me what you needed I would have sent you new lines. so let me know off line if youwant how I can help. I do have some AN 6 tubes; but the check valve would have to be modified, I can do that, to run AN6, but its not clear to me why its needed.... cheers john@powellraceparts.com

If you told me what you needed I would have sent you new lines. so let me know off line if youwant how I can help. I do have some AN 6 tubes; but the check valve would have to be modified, I can do that, to run AN6, but its not clear to me why its needed.... cheers john@powellraceparts.com

#238

For those folks running the filter on a stick under hood, you may well lose potential power due to the air density changing due to extreme under hood heat...just saying....

fyi

Banks Power | Air Density Testing

AND dont forget; if the valves are coked prior to putting on the upgrade, and you track the car, the coking that exists may already be causing issues. One significant issue I have found is inlet manifold PCV valves stuck open. A surprise to me and a bit of a shock, and if it is open, it really screws things up ....

#239

Going to ask a stupid question because I am a newb and I am stupid...lol

I am getting my car next weekend. I have been reading this forum and everywhere I go I read about the Powell Separator and how it is a first mod ...have to. The title of this is throwing me off LNF PCV Anti-coking drain back system...is this the separator that everyone is talking about or an advanced version...??

I am getting my car next weekend. I have been reading this forum and everywhere I go I read about the Powell Separator and how it is a first mod ...have to. The title of this is throwing me off LNF PCV Anti-coking drain back system...is this the separator that everyone is talking about or an advanced version...??

#240

Going to ask a stupid question because I am a newb and I am stupid...lol

I am getting my car next weekend. I have been reading this forum and everywhere I go I read about the Powell Separator and how it is a first mod ...have to. The title of this is throwing me off LNF PCV Anti-coking drain back system...is this the separator that everyone is talking about or an advanced version...??

I am getting my car next weekend. I have been reading this forum and everywhere I go I read about the Powell Separator and how it is a first mod ...have to. The title of this is throwing me off LNF PCV Anti-coking drain back system...is this the separator that everyone is talking about or an advanced version...??

#241

So I have been working with Alan Mcclure on the next step. Its very hard to produce parts and do research and work on cars etc. So Alan has been sharing the load with R&D esp. for LSJ-T variants.

We have concluded we need to induce more vacuum in the system. Why is vacuum important? All that oil and blow by vapor in the crankcase is getting flung around a lot. The outer edges of the crankshaft webs must be turning at 100 mph. Alan said to me tonight, imagine putting your hand out the window at a hundred miles per hour.

Imagine the poor piston at 6000 rpm; it is travelling up and down at the equvalent speed of about 30 miles per hour.

all that creates pressure in the crank case, and that pressure costs power. Oh and the piston accelleration speed increases as the square of the RPM. So does crank/rod bearing load .

We know from Wangspeeds comparisons, that he can drive for two weeks daily driving his turbo, ( a few hundred miles or more) and not collect more than 300 ml. of oil in the (non drain back) seperator. At the track he can collect 500 ml of oil in just twenty laps of racing, or say 50 miles.

so....if we can come up with a means to constantly maintain anout 15 inches of vacuum in the crankcase at all times, while continuing to seperate oil from the blow by gasses, then perhaps we can make more power ( sort of "free" power) and improve things like fuel economy, oil consumption, etc etc...and

no oil in the intake

on the track, racing, whereever.

that would be what we are working towards. In the meantime, with clean valves you can expect your LNF in normal dd work to maintain clean valves. Tune it, beat on it, track it, then its more difficult. Thats why v.3 of this system may well lead to some awesome results for racers.

We have concluded we need to induce more vacuum in the system. Why is vacuum important? All that oil and blow by vapor in the crankcase is getting flung around a lot. The outer edges of the crankshaft webs must be turning at 100 mph. Alan said to me tonight, imagine putting your hand out the window at a hundred miles per hour.

Imagine the poor piston at 6000 rpm; it is travelling up and down at the equvalent speed of about 30 miles per hour.

all that creates pressure in the crank case, and that pressure costs power. Oh and the piston accelleration speed increases as the square of the RPM. So does crank/rod bearing load .

We know from Wangspeeds comparisons, that he can drive for two weeks daily driving his turbo, ( a few hundred miles or more) and not collect more than 300 ml. of oil in the (non drain back) seperator. At the track he can collect 500 ml of oil in just twenty laps of racing, or say 50 miles.

so....if we can come up with a means to constantly maintain anout 15 inches of vacuum in the crankcase at all times, while continuing to seperate oil from the blow by gasses, then perhaps we can make more power ( sort of "free" power) and improve things like fuel economy, oil consumption, etc etc...and

no oil in the intake

on the track, racing, whereever.

that would be what we are working towards. In the meantime, with clean valves you can expect your LNF in normal dd work to maintain clean valves. Tune it, beat on it, track it, then its more difficult. Thats why v.3 of this system may well lead to some awesome results for racers.

Last edited by Powell Race Parts; 06-10-2014 at 11:53 PM.

#242

Not sure what you guys are cooking up, but back in my DSM'er days it was pretty common to use LT1 smog pumps as impromptu crankcase evacuation pumps. We stole the idea from the turbo Buick guys as I recall...

Like people had Hobbs switches and stuff like that controlling them.

Like people had Hobbs switches and stuff like that controlling them.

#243

Not sure what you guys are cooking up, but back in my DSM'er days it was pretty common to use LT1 smog pumps as impromptu crankcase evacuation pumps. We stole the idea from the turbo Buick guys as I recall...

Like people had Hobbs switches and stuff like that controlling them.

Like people had Hobbs switches and stuff like that controlling them.

#245

nothing

Arduino is a single-board microcontroller, intended to make the application of interactive objects or environments more accessible.[1] The hardware consists of an open-source hardware board designed around an 8-bit Atmel AVR microcontroller, or a 32-bit Atmel ARM. Current models feature a USB interface, 6 analog input pins, as well as 14 digital I/O pins which allows the user to attach various extension boards.

still nothing.

Arduino is a single-board microcontroller, intended to make the application of interactive objects or environments more accessible.[1] The hardware consists of an open-source hardware board designed around an 8-bit Atmel AVR microcontroller, or a 32-bit Atmel ARM. Current models feature a USB interface, 6 analog input pins, as well as 14 digital I/O pins which allows the user to attach various extension boards.

still nothing.

#246

So I have been working with Alan Mcclure on the next step. Its very hard to produce parts and do research and work on cars etc. So Alan has been sharing the load with R&D esp. for LSJ-T variants.

We have concluded we need to induce more vacuum in the system. Why is vacuum important? All that oil and blow by vapor in the crankcase is getting flung around a lot. The outer edges of the crankshaft webs must be turning at 100 mph. Alan said to me tonight, imagine putting your hand out the window at a hundred miles per hour.

Imagine the poor piston at 6000 rpm; it is travelling up and down at the equvalent speed of about 30 miles per hour.

all that creates pressure in the crank case, and that pressure costs power. Oh and the piston accelleration speed increases as the square of the RPM. So does crank/rod bearing load .

We know from Wangspeeds comparisons, that he can drive for two weeks daily driving his turbo, ( a few hundred miles or more) and not collect more than 300 ml. of oil in the (non drain back) seperator. At the track he can collect 500 ml of oil in just twenty laps of racing, or say 50 miles.

so....if we can come up with a means to constantly maintain anout 15 inches of vacuum in the crankcase at all times, while continuing to seperate oil from the blow by gasses, then perhaps we can make more power ( sort of "free" power) and improve things like fuel economy, oil consumption, etc etc...and

no oil in the intake

on the track, racing, whereever.

that would be what we are working towards. In the meantime, with clean valves you can expect your LNF in normal dd work to maintain clean valves. Tune it, beat on it, track it, then its more difficult. Thats why v.3 of this system may well lead to some awesome results for racers.

We have concluded we need to induce more vacuum in the system. Why is vacuum important? All that oil and blow by vapor in the crankcase is getting flung around a lot. The outer edges of the crankshaft webs must be turning at 100 mph. Alan said to me tonight, imagine putting your hand out the window at a hundred miles per hour.

Imagine the poor piston at 6000 rpm; it is travelling up and down at the equvalent speed of about 30 miles per hour.

all that creates pressure in the crank case, and that pressure costs power. Oh and the piston accelleration speed increases as the square of the RPM. So does crank/rod bearing load .

We know from Wangspeeds comparisons, that he can drive for two weeks daily driving his turbo, ( a few hundred miles or more) and not collect more than 300 ml. of oil in the (non drain back) seperator. At the track he can collect 500 ml of oil in just twenty laps of racing, or say 50 miles.

so....if we can come up with a means to constantly maintain anout 15 inches of vacuum in the crankcase at all times, while continuing to seperate oil from the blow by gasses, then perhaps we can make more power ( sort of "free" power) and improve things like fuel economy, oil consumption, etc etc...and

no oil in the intake

on the track, racing, whereever.

that would be what we are working towards. In the meantime, with clean valves you can expect your LNF in normal dd work to maintain clean valves. Tune it, beat on it, track it, then its more difficult. Thats why v.3 of this system may well lead to some awesome results for racers.

#247

#248

thats odd. I can send you a new seperator, tube and lines , you have the check valve. that way, you can stop whats happening to you, just mail back the old parts, thats the only cost to you . That way you have a fresh filter with the seperator, and the (to me) correct drain back lines etc... email me your shipping address so I can send that out right away, please.

#249

tapered end goes to the dipstick tube ; the fittings are installed so there is male on the seperator to joint the drain back female fittings; female an 4 to go to the male seperator 90 degree lower fitting which you must have changed unless this was a totally early model version I did?

#250

tapered end goes to the dipstick tube ; the fittings are installed so there is male on the seperator to joint the drain back female fittings; female an 4 to go to the male seperator 90 degree lower fitting which you must have changed unless this was a totally early model version I did?