Mark this thread as Unsold

FS: P&P M62 case

#1

#3

Thanks

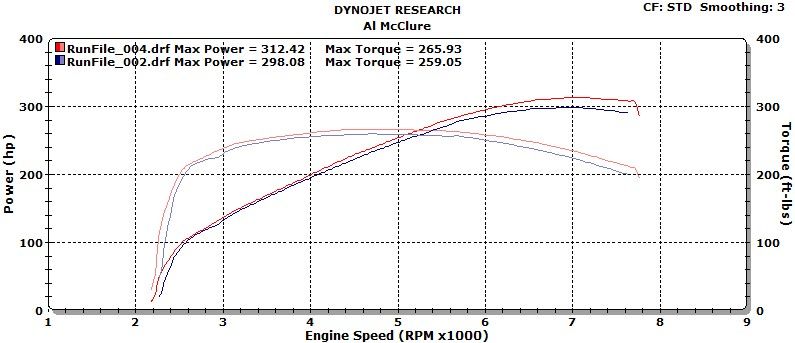

Thought I would add this as well. This test was done with the car still strapped down, swapped blowers on the rollers.

The low graph is my original blower with a 2.6

Inlet opened for ls4 but not polished.

High graph is a blower with this outlet port only, spacer used for ls4 (less than ideal). Same 2.6 pulley.

----And side note, these graphs are in std. My 309 graph in the dyno thread was a 2.5, ported outlet, done the same day, but I accidentally uploaded the sae graph before seeing most people use std. Std on the 2.5 was 317

Thought I would add this as well. This test was done with the car still strapped down, swapped blowers on the rollers.

The low graph is my original blower with a 2.6

Inlet opened for ls4 but not polished.

High graph is a blower with this outlet port only, spacer used for ls4 (less than ideal). Same 2.6 pulley.

----And side note, these graphs are in std. My 309 graph in the dyno thread was a 2.5, ported outlet, done the same day, but I accidentally uploaded the sae graph before seeing most people use std. Std on the 2.5 was 317

#5

Joined: 12-30-07

Posts: 14,331

Likes: 197

From: NEPA

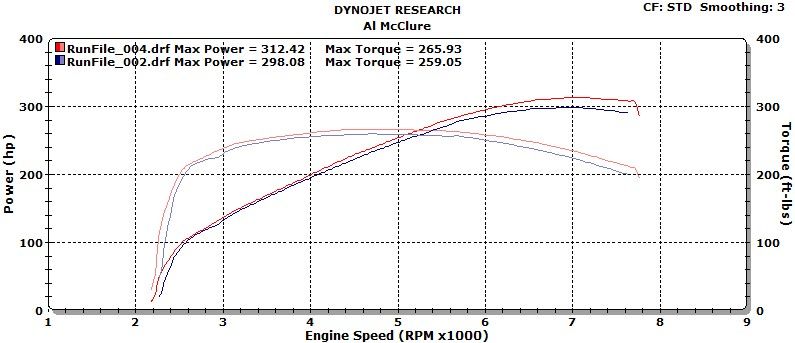

Thanks

Thought I would add this as well. This test was done with the car still strapped down, swapped blowers on the rollers.

The low graph is my original blower with a 2.6

Inlet opened for ls4 but not polished.

High graph is a blower with this outlet port only, spacer used for ls4 (less than ideal). Same 2.6 pulley.

----And side note, these graphs are in std. My 309 graph in the dyno thread was a 2.5, ported outlet, done the same day, but I accidentally uploaded the sae graph before seeing most people use std. Std on the 2.5 was 317

Thought I would add this as well. This test was done with the car still strapped down, swapped blowers on the rollers.

The low graph is my original blower with a 2.6

Inlet opened for ls4 but not polished.

High graph is a blower with this outlet port only, spacer used for ls4 (less than ideal). Same 2.6 pulley.

----And side note, these graphs are in std. My 309 graph in the dyno thread was a 2.5, ported outlet, done the same day, but I accidentally uploaded the sae graph before seeing most people use std. Std on the 2.5 was 317

#11

#12

#13

Joined: 12-30-07

Posts: 14,331

Likes: 197

From: NEPA

#14

Yep. Once it's off the car it takes 10 min. If you're careful you can even do it without draining the oil. But if you haven't done it recently I would recommend a coupler and oil to go along with it.

#16

Joined: 12-30-07

Posts: 14,331

Likes: 197

From: NEPA

#17

That has been battled back and forth for years. For a blower operating within the oe compressor map, yes there is little to no gain and possible damage.

Very few people here are still on the map.

This general design has been tested many times by several different people/companies to provide a gain when done properly.

This is not a dremel job. I matched the widest split close to the leading rotor closing point, done by hand. Then put in a cmm to digitize, and corrected the edges to match the rotor twist like stock. Then used a cnc to make a jig so that each one is done perfectly.

Even eaton admitted there are possible gains by porting.

We are forcing these blowers into territory they were never designed for with our small pullies, and this helps bring the effeciency back up. This case is NOT for someone running a stock/stg2 pulley.

Very few people here are still on the map.

This general design has been tested many times by several different people/companies to provide a gain when done properly.

This is not a dremel job. I matched the widest split close to the leading rotor closing point, done by hand. Then put in a cmm to digitize, and corrected the edges to match the rotor twist like stock. Then used a cnc to make a jig so that each one is done perfectly.

Even eaton admitted there are possible gains by porting.

We are forcing these blowers into territory they were never designed for with our small pullies, and this helps bring the effeciency back up. This case is NOT for someone running a stock/stg2 pulley.

#22

#24

Joined: 12-30-07

Posts: 14,331

Likes: 197

From: NEPA

#25

Thats why I am asking.