2.4 LE5 Tuning FAQ

#1

DISCLAIMER - I AM NOT RESPONSIBLE FOR THE CHANGES YOU MAKE TO YOUR CAR. Do at your own risk!

All right guys, seeing as how a lot of the 2.4's are getting tuned. I though that I would put this up. This is the very first thing that you should do to bring down the IDC's. Remember that even stock I have logged my IDC's getting as high as 98%. Now with bolt on's it is well over 100% which mean the injectors might go static.

These first steps were told to me from (BennyHHR) on the HPT forum.

In the HPT Editor:

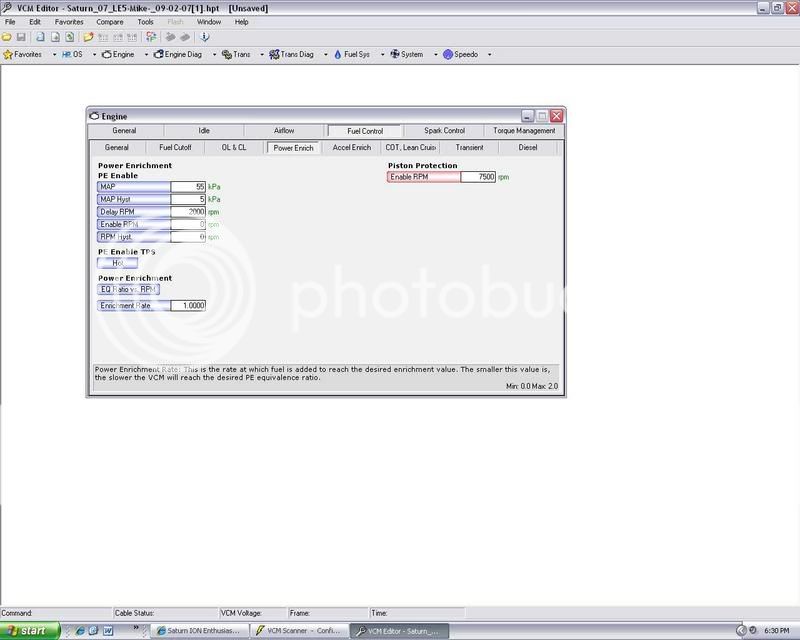

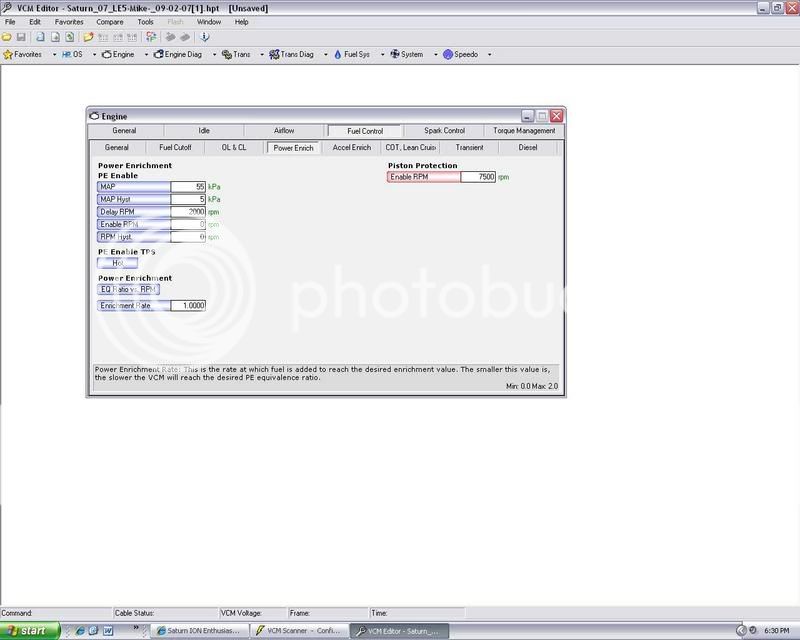

Engine, Fuel Control, Power Enrich and change the

Following settings:

Delay RPM: set to 2000

EQ Ratio vs. RPM: set the whole table to 1.140 which equals’ a 12.9 AFR.

Enrichment Rate: set to 1.0

Piston Protection: set Enable RPM to 7500

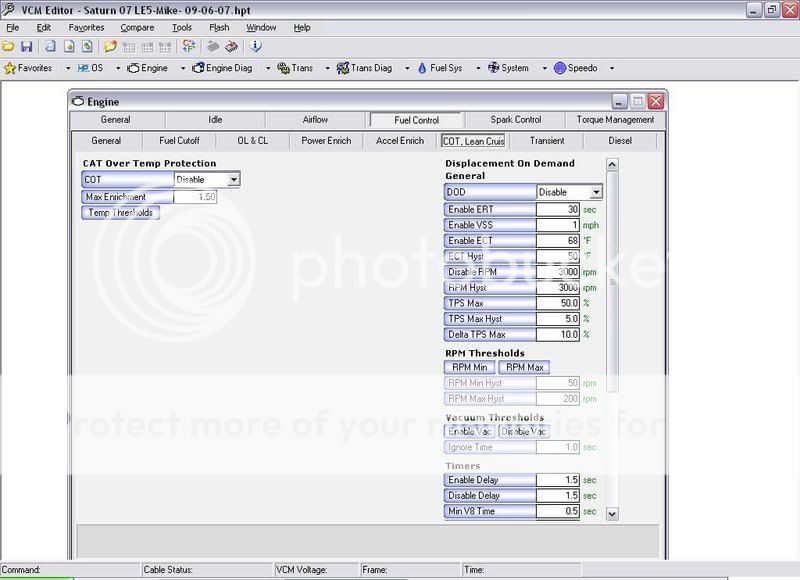

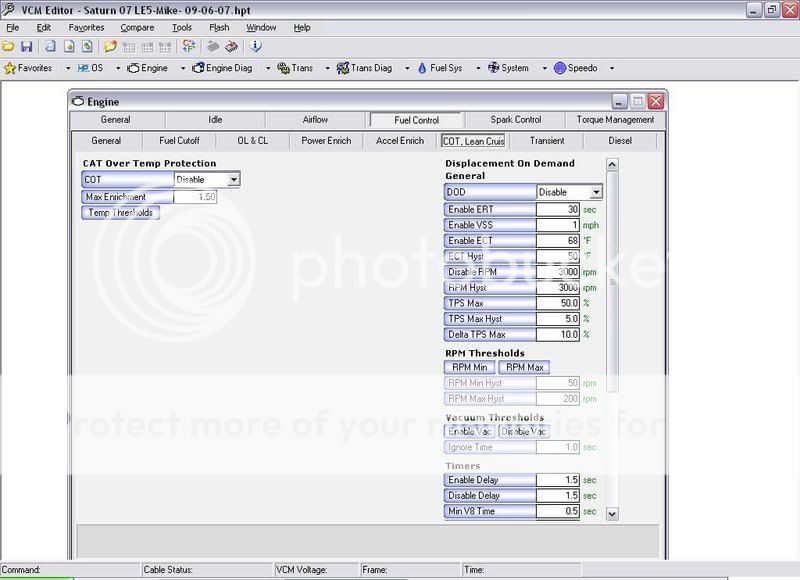

Then, under the COT, Lean Cruise tab, Cat over Temp

Protection:

COT: set to disable

[img]

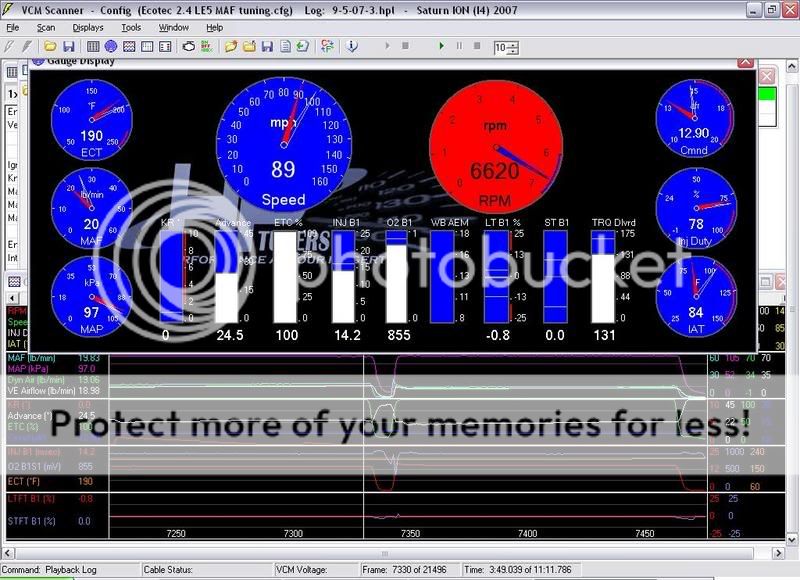

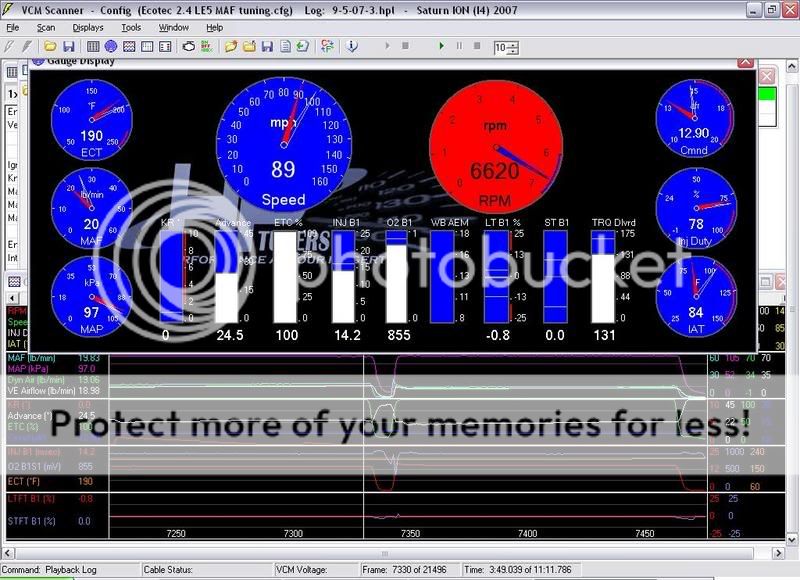

In doing this it should bring your IDC's down. Here is a screen shot of a log I have done, and you can see the results for you self 8)

Setting up Histograms

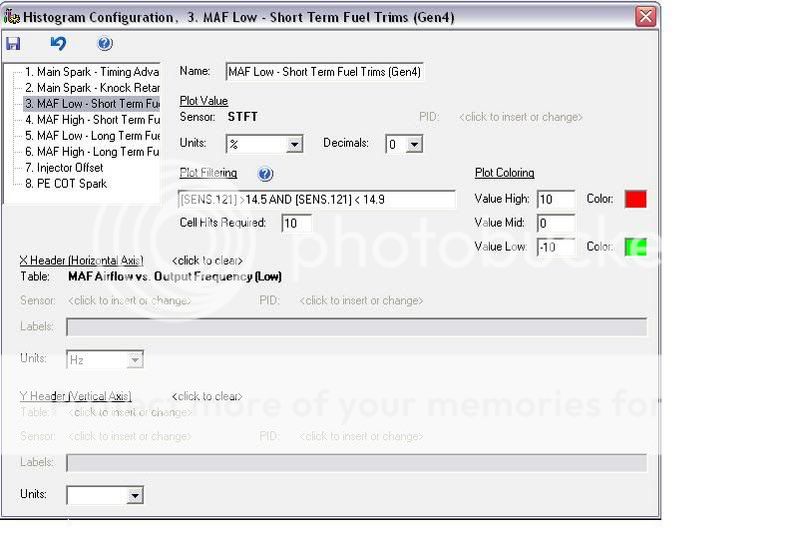

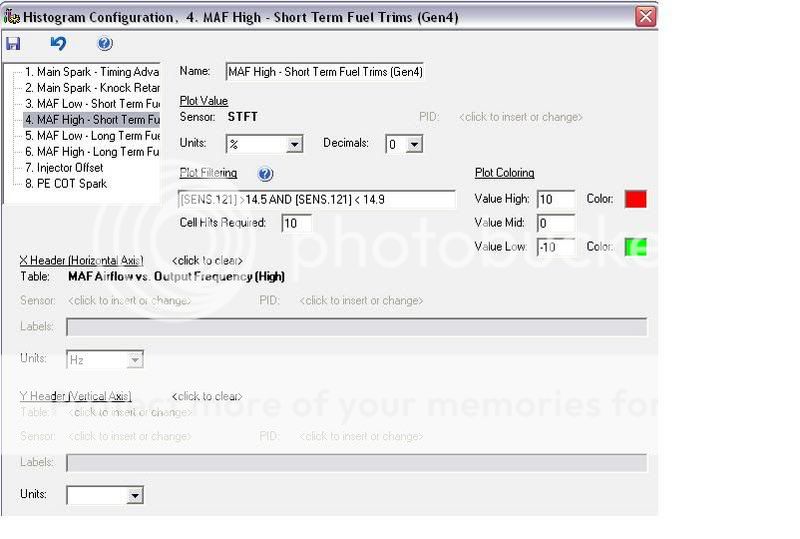

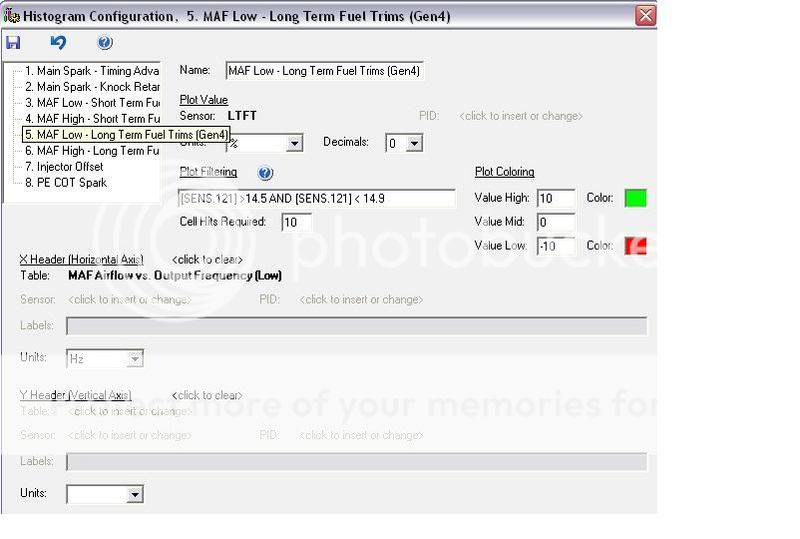

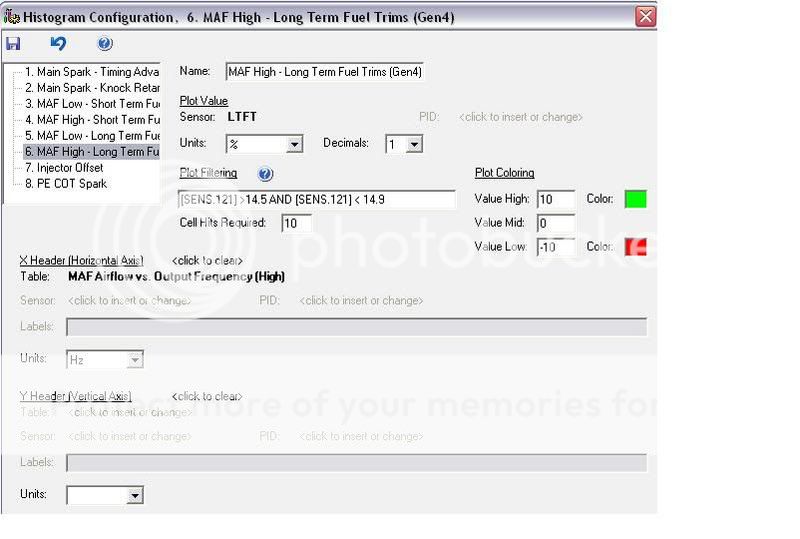

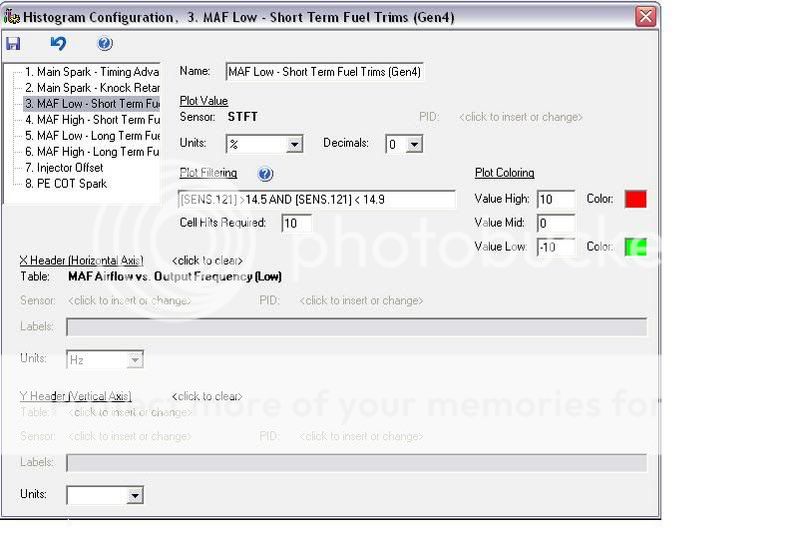

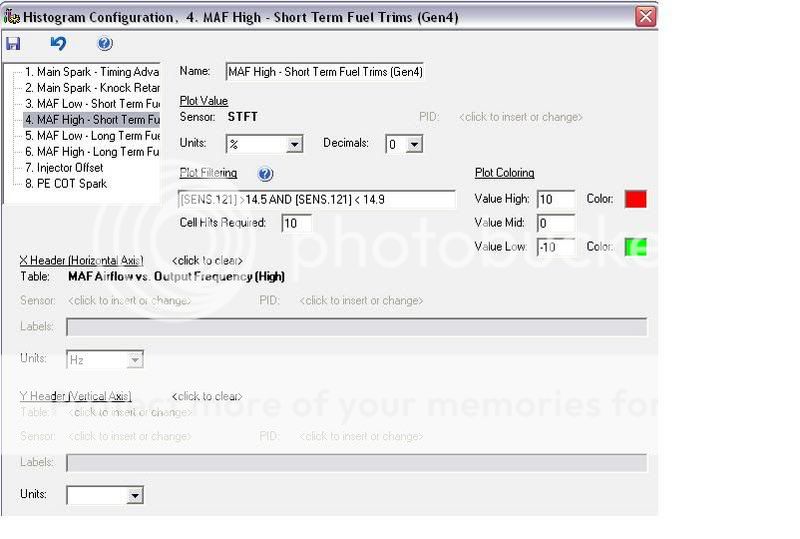

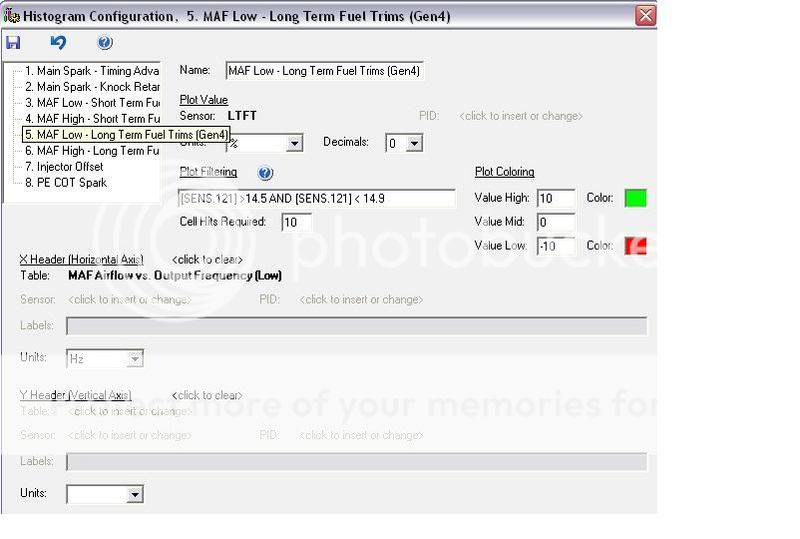

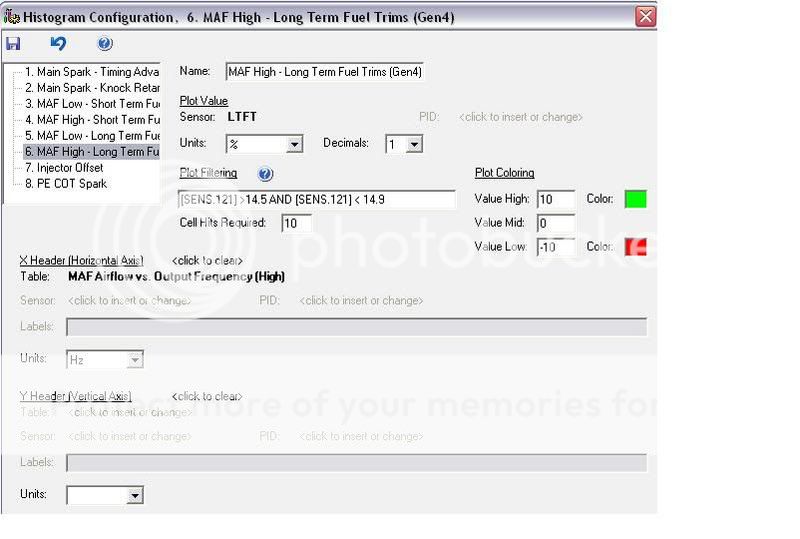

Now after doing this I would go ahead and start tuning the MAF transfer for the High and Low freq tables. Normally you would want to start tuning the VE table, but seeing how the E67 ECM has Dynamic airflow zones instead of a main VE we can’t. So to get the info for the MAF you are going to need to log the error ratio in the VCM Scanner after you set up your histograms. Then you are going to put a filter in there to ignore anything after going to PE, or DFCO. To do this you are going to need to set up four histograms. One for STFT high and low freq and one foe LTFT low and high. To do this, go into the scanner and under Plot Value, click on sensor and scroll down to STFT. And then under the X header- click the table and select MAF Airflow vs. freq high. And then for the next one you would click MAF Airflow freq low. And now you will be able to plot your STFT's. For the LTFT's it is the same thing, but under sensor you would click LTFT.

Now for the Filter strings to block out PE and DFCO. You would want to enter.

STFT's low freq= [SENS.121] >14.5 AND [SENS.121] < 14.9

STFT's High Freq= [SENS.121] >14.5 AND [SENS.121] < 14.9

LTFT's Low Freg= [SENS.121] >14.5 AND [SENS.121] < 14.9

LTFT's High Freq= [SENS.121] >14.5 AND [SENS.121] < 14.9

Notes: You would only do this if you do not have a wideband gauge. There is a different why to do this with a wideband.

* For MAF tuning: Look toward applying trims to MAF tables via "Copy, Paste Special, Multiply by %" (then by 1/2 to zero in). Remember the more data, the more accurate. Best to clear LTFTs before starting to have data more current. The jury still seems to be out as to whether to use STFT or LTFT for this process, however if the LTFT are cleared before starting, it shouldn't really make much difference. Also good to smooth MAF tables before finalizing to be consistent and this should help get rid of any "blips" from data. With the inability to tune the high load / high rpm range with this method, I like to "extrapolate" the upper end from the trend approaching that. That should at least get the upper end in the ballpark.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

* Wideband: Recommended best method. FT method is not as good nor as easy. For wideband method, I chose to write a similar to current tune that forces open loop and eliminates variables, clear FTs, log AFR error (H&L MAF) and use that over MAF tables. When you have the capability, we can go over that more.

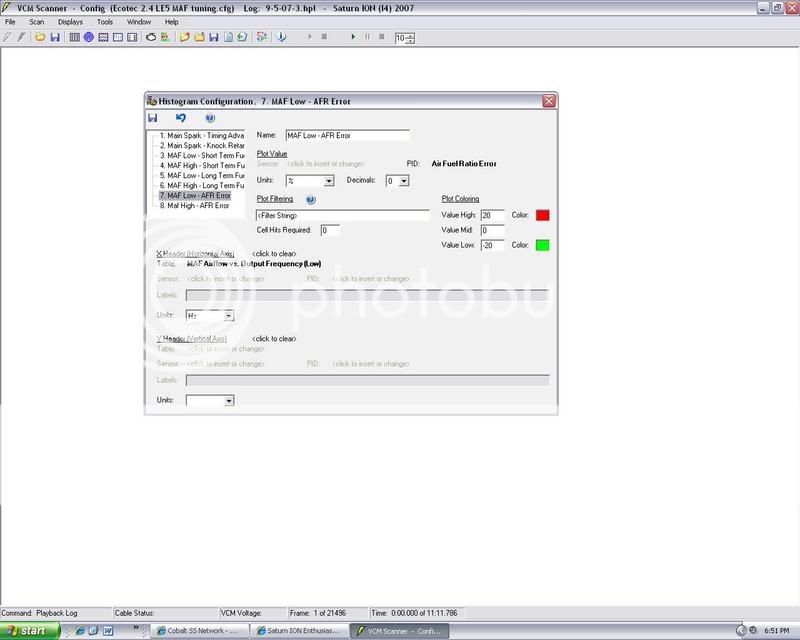

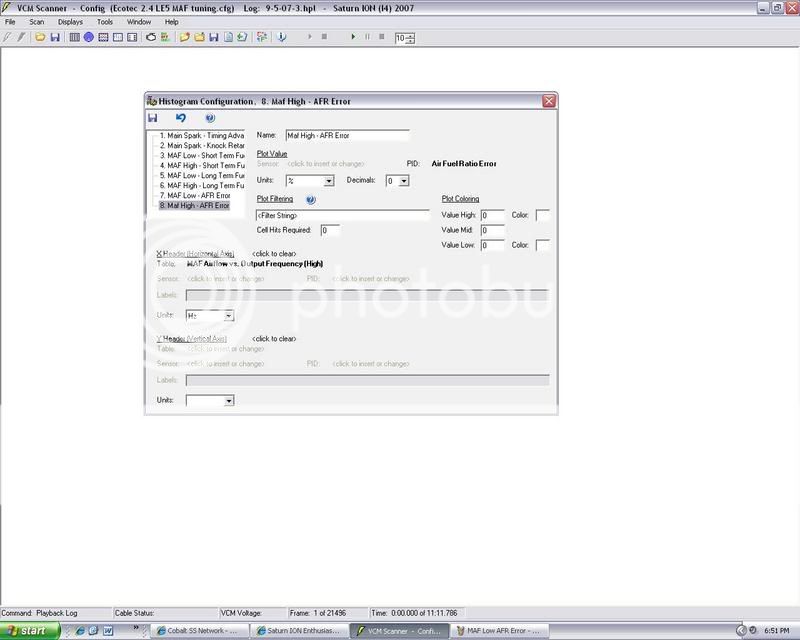

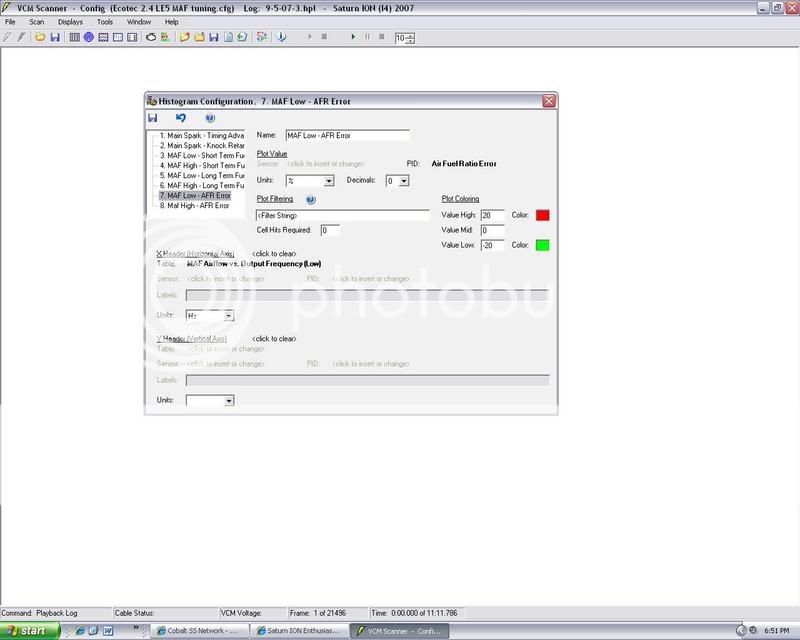

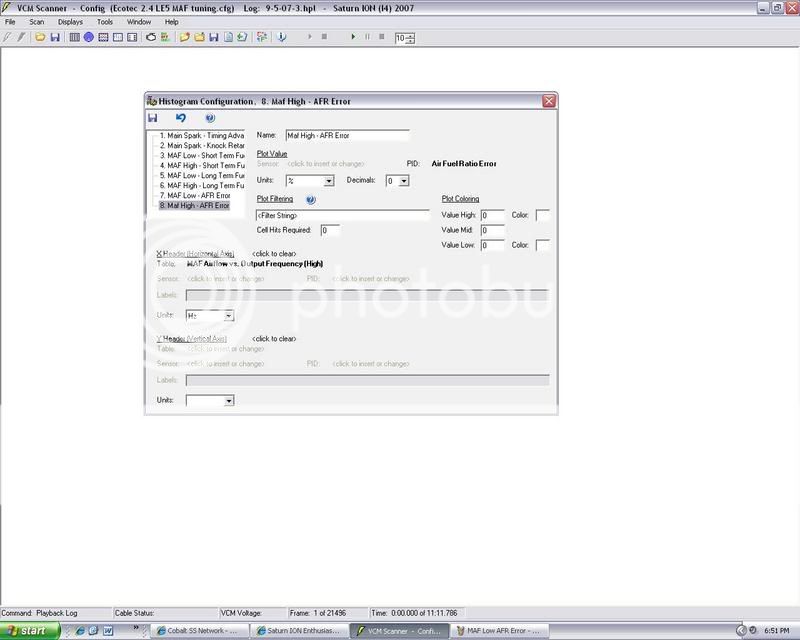

Just like you set up the Histograms for logging the MAF Low and High with the fuel trims, you need to set up two histograms for the AFR Error to log the MAF. This is by far a lot more accurate then using the fuel trims.

For the MAF Low AFR Error Histogram looks like this

The MAF High AFR Error looks like this.

Note: These will only work if you have a Wideband O2 sensor and are able to log it with the MPVI Pro interface from HPT. You will also have to set up the PID’s for AFFR Error and one for the wide band itself

How to Bump Rev Limater

All right guys here is a new one. After you have taken the step above you most likely want to raise you rev limiter.

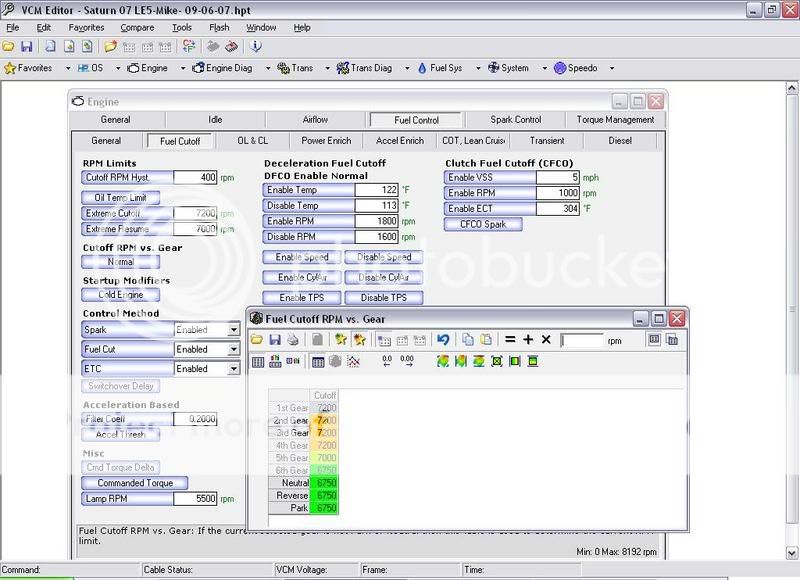

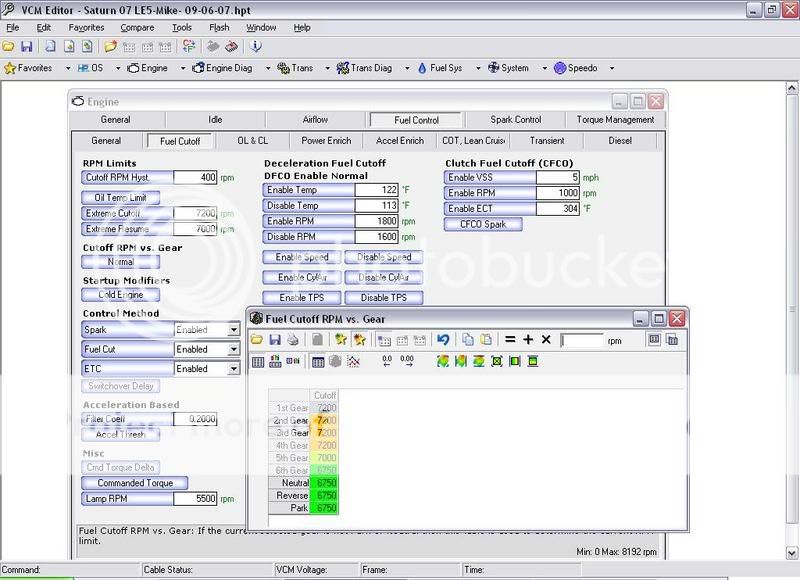

Go to Engine>Fuel Control>Fuel cutoff

Then select "Fuel cutoff vs. gear" you can change in here.

Here is a screen shoot of mine

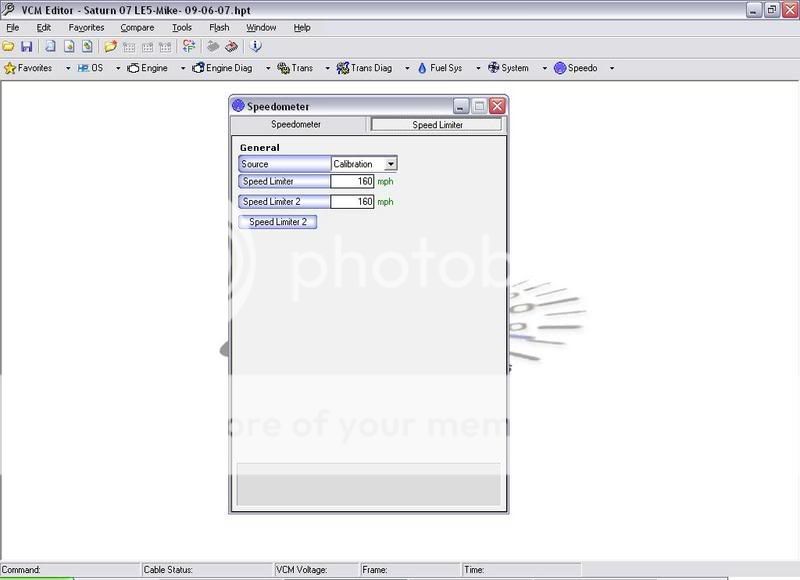

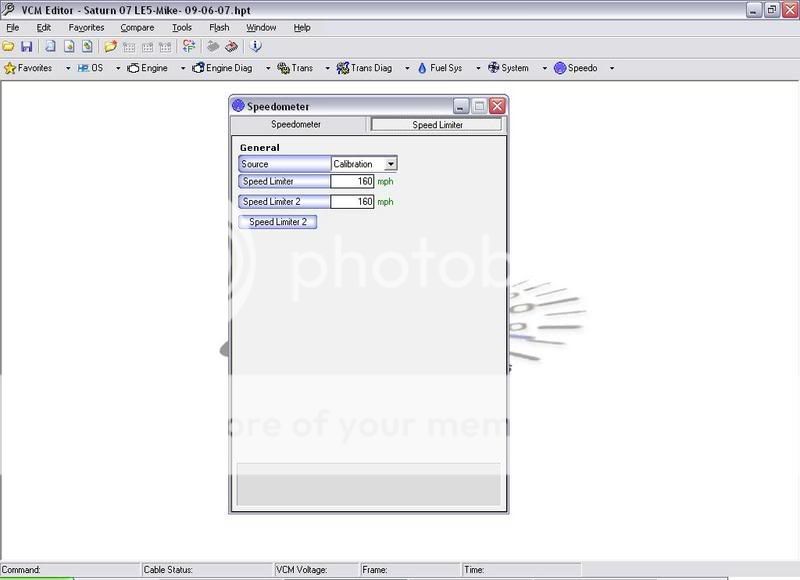

Also now would be a good time to bump up your speed limiter

Click on Speedo>Speed limiter Now you can set it to whatever you want.

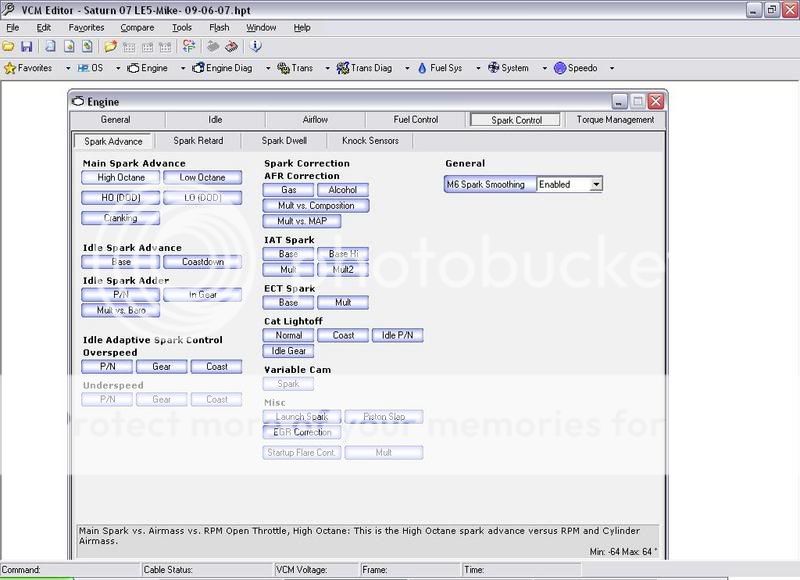

Adding Timing

Now you want to add some time

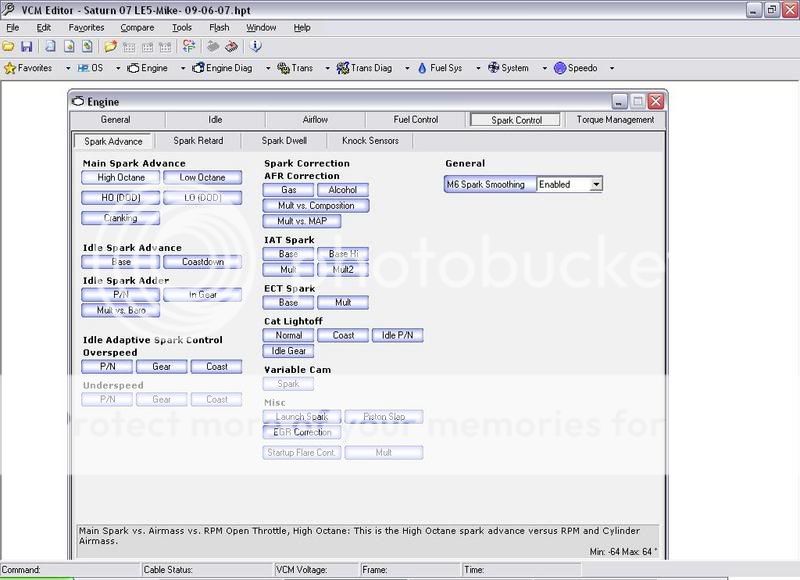

Go to Engine tab

Clink on Spark Control>Spark Advance

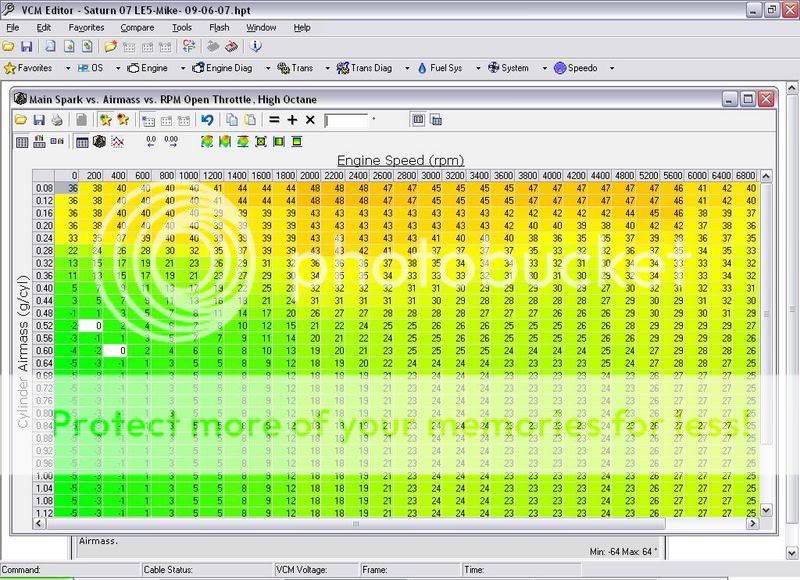

It should look like this

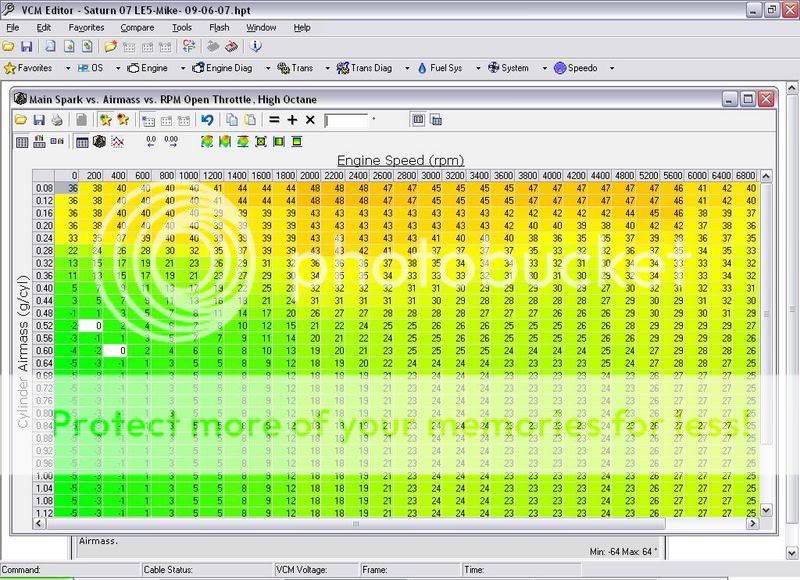

Now click on the High Octane table and highlight the whole screen and at the top you can see the a spot to put a number and the click the add sign

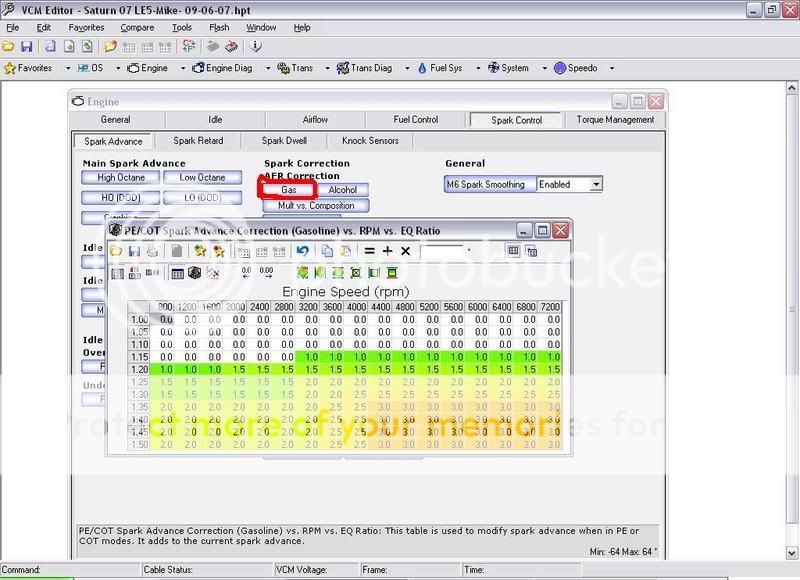

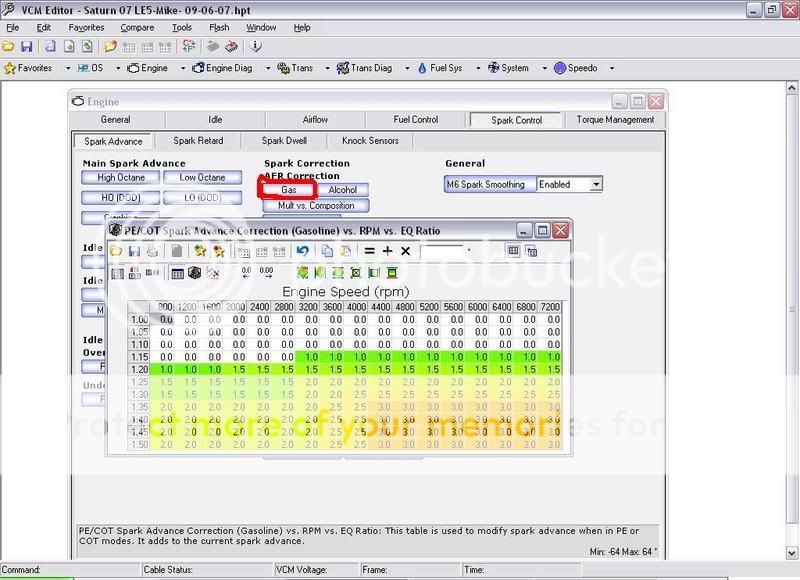

Also you have another table that adds timing on top of your high octane table. You PE/COT sparks correction table. Some say that you can just zero this table out and only rely on you high octane table. Others say just to leave it alone. I will leave this up to you.

Too find this table go to your spark advance table and then under the heading Spark correction click than GAS tab.

Here is a screen shot

Note:

Spark:Start out copying the HO table to the LO to get consistent data. Remember, given gas quality, temp, etc. that our ECM will "average down" if knock is detected. I like to eliminate that while spark tuning, focusing on the HO, with the LO being the same. Suggest adding about 2*, log watching for KR, rinse, repeat.... Until all KR is gone. Then smooth the HO table. Once clean of KR, I like to then subtract 3 or 4 deg. from the LO table. And that's only if you only use the same octane gas. The amount should be larger if someone tunes for higher octane and sometimes uses lower octane to have more allowance.

Torque Management

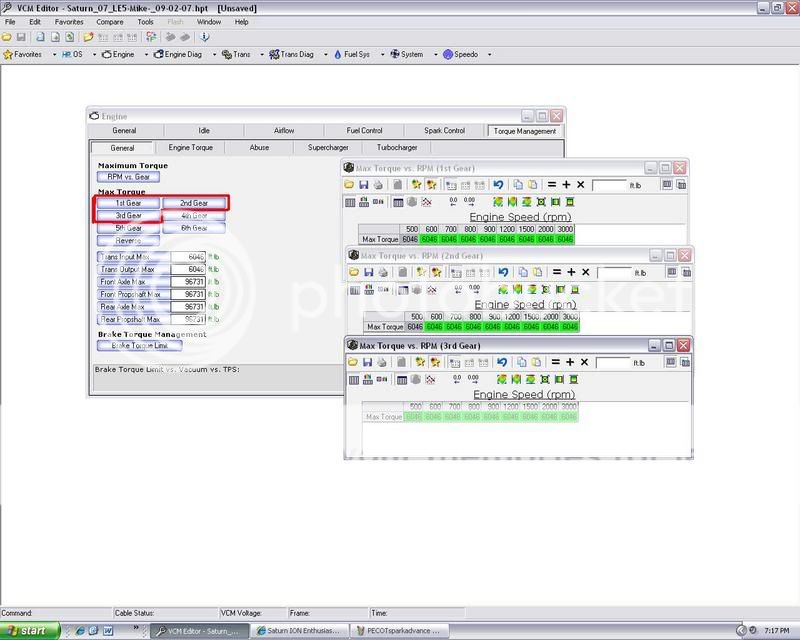

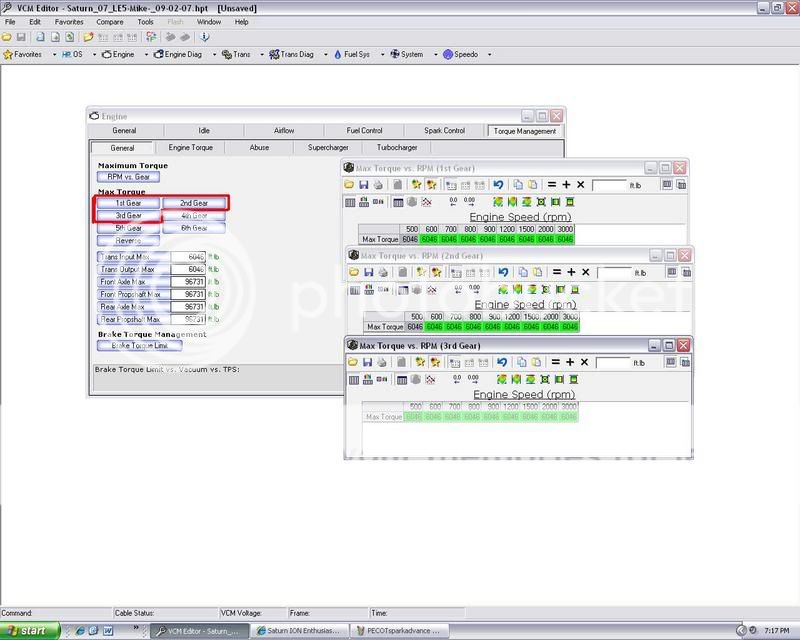

Alright everyone, now the next thing that you could do is to remove the Torque Management, luckily this is a rather easy one.

First open up your VCM Editor and go to the General Engine tab.

Next thing you need to do is to open up the “Max Torque” 1st, 2nd, and 3rd tabs should look like this. And change all the values to ‘6046’ which is the maximum value. This will remove the TQ management in those gears, you can do this for 4th and 5th as well but I do not believe that it is needed.

I will update the thread from time to time. When I get more info.

All right guys, seeing as how a lot of the 2.4's are getting tuned. I though that I would put this up. This is the very first thing that you should do to bring down the IDC's. Remember that even stock I have logged my IDC's getting as high as 98%. Now with bolt on's it is well over 100% which mean the injectors might go static.

These first steps were told to me from (BennyHHR) on the HPT forum.

In the HPT Editor:

Engine, Fuel Control, Power Enrich and change the

Following settings:

Delay RPM: set to 2000

EQ Ratio vs. RPM: set the whole table to 1.140 which equals’ a 12.9 AFR.

Enrichment Rate: set to 1.0

Piston Protection: set Enable RPM to 7500

Then, under the COT, Lean Cruise tab, Cat over Temp

Protection:

COT: set to disable

[img]

In doing this it should bring your IDC's down. Here is a screen shot of a log I have done, and you can see the results for you self 8)

Setting up Histograms

Now after doing this I would go ahead and start tuning the MAF transfer for the High and Low freq tables. Normally you would want to start tuning the VE table, but seeing how the E67 ECM has Dynamic airflow zones instead of a main VE we can’t. So to get the info for the MAF you are going to need to log the error ratio in the VCM Scanner after you set up your histograms. Then you are going to put a filter in there to ignore anything after going to PE, or DFCO. To do this you are going to need to set up four histograms. One for STFT high and low freq and one foe LTFT low and high. To do this, go into the scanner and under Plot Value, click on sensor and scroll down to STFT. And then under the X header- click the table and select MAF Airflow vs. freq high. And then for the next one you would click MAF Airflow freq low. And now you will be able to plot your STFT's. For the LTFT's it is the same thing, but under sensor you would click LTFT.

Now for the Filter strings to block out PE and DFCO. You would want to enter.

STFT's low freq= [SENS.121] >14.5 AND [SENS.121] < 14.9

STFT's High Freq= [SENS.121] >14.5 AND [SENS.121] < 14.9

LTFT's Low Freg= [SENS.121] >14.5 AND [SENS.121] < 14.9

LTFT's High Freq= [SENS.121] >14.5 AND [SENS.121] < 14.9

Notes: You would only do this if you do not have a wideband gauge. There is a different why to do this with a wideband.

* For MAF tuning: Look toward applying trims to MAF tables via "Copy, Paste Special, Multiply by %" (then by 1/2 to zero in). Remember the more data, the more accurate. Best to clear LTFTs before starting to have data more current. The jury still seems to be out as to whether to use STFT or LTFT for this process, however if the LTFT are cleared before starting, it shouldn't really make much difference. Also good to smooth MAF tables before finalizing to be consistent and this should help get rid of any "blips" from data. With the inability to tune the high load / high rpm range with this method, I like to "extrapolate" the upper end from the trend approaching that. That should at least get the upper end in the ballpark.

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

* Wideband: Recommended best method. FT method is not as good nor as easy. For wideband method, I chose to write a similar to current tune that forces open loop and eliminates variables, clear FTs, log AFR error (H&L MAF) and use that over MAF tables. When you have the capability, we can go over that more.

Just like you set up the Histograms for logging the MAF Low and High with the fuel trims, you need to set up two histograms for the AFR Error to log the MAF. This is by far a lot more accurate then using the fuel trims.

For the MAF Low AFR Error Histogram looks like this

The MAF High AFR Error looks like this.

Note: These will only work if you have a Wideband O2 sensor and are able to log it with the MPVI Pro interface from HPT. You will also have to set up the PID’s for AFFR Error and one for the wide band itself

How to Bump Rev Limater

All right guys here is a new one. After you have taken the step above you most likely want to raise you rev limiter.

Go to Engine>Fuel Control>Fuel cutoff

Then select "Fuel cutoff vs. gear" you can change in here.

Here is a screen shoot of mine

Also now would be a good time to bump up your speed limiter

Click on Speedo>Speed limiter Now you can set it to whatever you want.

Adding Timing

Now you want to add some time

Go to Engine tab

Clink on Spark Control>Spark Advance

It should look like this

Now click on the High Octane table and highlight the whole screen and at the top you can see the a spot to put a number and the click the add sign

Also you have another table that adds timing on top of your high octane table. You PE/COT sparks correction table. Some say that you can just zero this table out and only rely on you high octane table. Others say just to leave it alone. I will leave this up to you.

Too find this table go to your spark advance table and then under the heading Spark correction click than GAS tab.

Here is a screen shot

Note:

Spark:Start out copying the HO table to the LO to get consistent data. Remember, given gas quality, temp, etc. that our ECM will "average down" if knock is detected. I like to eliminate that while spark tuning, focusing on the HO, with the LO being the same. Suggest adding about 2*, log watching for KR, rinse, repeat.... Until all KR is gone. Then smooth the HO table. Once clean of KR, I like to then subtract 3 or 4 deg. from the LO table. And that's only if you only use the same octane gas. The amount should be larger if someone tunes for higher octane and sometimes uses lower octane to have more allowance.

Torque Management

Alright everyone, now the next thing that you could do is to remove the Torque Management, luckily this is a rather easy one.

First open up your VCM Editor and go to the General Engine tab.

Next thing you need to do is to open up the “Max Torque” 1st, 2nd, and 3rd tabs should look like this. And change all the values to ‘6046’ which is the maximum value. This will remove the TQ management in those gears, you can do this for 4th and 5th as well but I do not believe that it is needed.

I will update the thread from time to time. When I get more info.

Last edited by REDFOCZ; 06-04-2008 at 07:21 PM. Reason: Removed some info

#8

is this what ya gotta do to tune the LE5? Cuz my friend has HP Tuners, and will let me use it to tune my car. I just don't have anyone to tune it, unless someone would be nice enough to email me the tuning files for the 2.4 with auto tranny.

#11

#12

#13

lol oops...I haven't really looked at a 2.4 tune yet...I was looking at the 2.0 lnf though..somewhat confusing and everything isn't even unlocked yet

#14

I would think you would want to filter air metering to use only MAF if you are only tuning a MAF. Without seperating the two (MAP + MAF = Dynamic), you would be incorporating any VE errors into your MAF calibration since your trims and air/fuel if using a wideband is still using partial VE to calculate incoming airflow.

#15

I would think you would want to filter air metering to use only MAF if you are only tuning a MAF. Without seperating the two (MAP + MAF = Dynamic), you would be incorporating any VE errors into your MAF calibration since your trims and air/fuel if using a wideband is still using partial VE to calculate incoming airflow.

#16

I recently put Vista 64 on my desktop so I don't have HPTuners on it yet so I can't reference it right now, but if you are tuning MAF, under the dynamic airflow tab you'll want to change the setting that says something along the lines of "Trusted MAF airflow" to an rpm less than your idle. This way the PCM never references the VE in the dynamic airflow calculation.

If its using a VE/MAF blend, then any errors in your VE will carry over into your MAF tune. For example, your VE is 10% lean at "X" amount of airflow, however your MAF value "Y" is accurate at that same point. Now your trim may say you are lean by 5% so you now have leaned out your MAF "Y" by 5% from a previously accurate value ([X+Y]/2=dynamic or the fueling value). Although there isn't currently a way to fix the VE portion, its no reason to fudge it with the MAF because those same two values may not match up again if the temperature or weather changes (ie. "X" may now match up with "Y+10" when the air is colder and more dense).

Oversimplified for forum sake.

If its using a VE/MAF blend, then any errors in your VE will carry over into your MAF tune. For example, your VE is 10% lean at "X" amount of airflow, however your MAF value "Y" is accurate at that same point. Now your trim may say you are lean by 5% so you now have leaned out your MAF "Y" by 5% from a previously accurate value ([X+Y]/2=dynamic or the fueling value). Although there isn't currently a way to fix the VE portion, its no reason to fudge it with the MAF because those same two values may not match up again if the temperature or weather changes (ie. "X" may now match up with "Y+10" when the air is colder and more dense).

Oversimplified for forum sake.

#17

I knew that when tuning for a boosted applications that you would want to disable the Dynamic airflow and have it set to trust only the MAF. I have thought about it on a N/A app but just have not gone out and tried it. I know on the new Gen 4 V8’s that have the E67 & E38 that is trust only the MAF after 3600 RPM’s and all. I will try it out and let you know.

#18

I knew that when tuning for a boosted applications that you would want to disable the Dynamic airflow and have it set to trust only the MAF. I have thought about it on a N/A app but just have not gone out and tried it. I know on the new Gen 4 V8’s that have the E67 & E38 that is trust only the MAF after 3600 RPM’s and all. I will try it out and let you know.

#22

although, the 2.4 does seem to be pretty easy to wake up... my car is just about stock, but with the intake, poly mounts, flywheel and clutch, it def is faster.

#24

not sure but i think it has something to do with changing the dynamic air flow....i think you have to set MAP to under idle rpm range and that should enable you to tune for maf...not even sure if im telling you right...this is strictly what ive heard...and i believe it was posted earlier in this thread...lol